Park Improvements to Create More Summer Fun in Pennsylvania

Pennsylvania, renowned for its rich history and stunning landscapes, boasts a variety of parks catering to nature enthusiasts and history buffs alike. As well as providing opportunities for outdoor activities and exercise, these green spaces also serve as gateways to the region's rich history. Many of these parks have humble beginnings, often emerging from popular sites, family estates, or repurposed abandoned properties. Over time, they have evolved into vibrant recreational areas adorned with playgrounds, tranquil walking trails, and refreshing splash pads.

Empire Services: Enhancing Reading's Parks

Empire Services has played a role in enhancing parks across Reading and beyond. Their contributions to park improvements have created safer, more enjoyable environments for families to gather, play, and connect with nature. From upgrading facilities to maintaining green spaces and implementing innovative features like splash pads, Empire Services has helped transform parks into vibrant centers of community life. Let’s take a look at a few of them.

City Park Enhancements

City Park, located near 11th and Walnut Streets in Reading, underwent significant improvements thanks to Empire Services. The project included the installation of an all-inclusive playground and a splash pad. As part of the preparation for these new amenities, utilities were upgraded and the site was carefully prepared. Adding fencing and improved walking trails enhanced the park's appeal and accessibility.

Baer Park Upgrades

Empire Services also contributed to improvements at Baer Park, another cherished space in Reading. The project involved preparing the park for new play areas, including grading and compacting the subgrade for a new concrete splash pad.

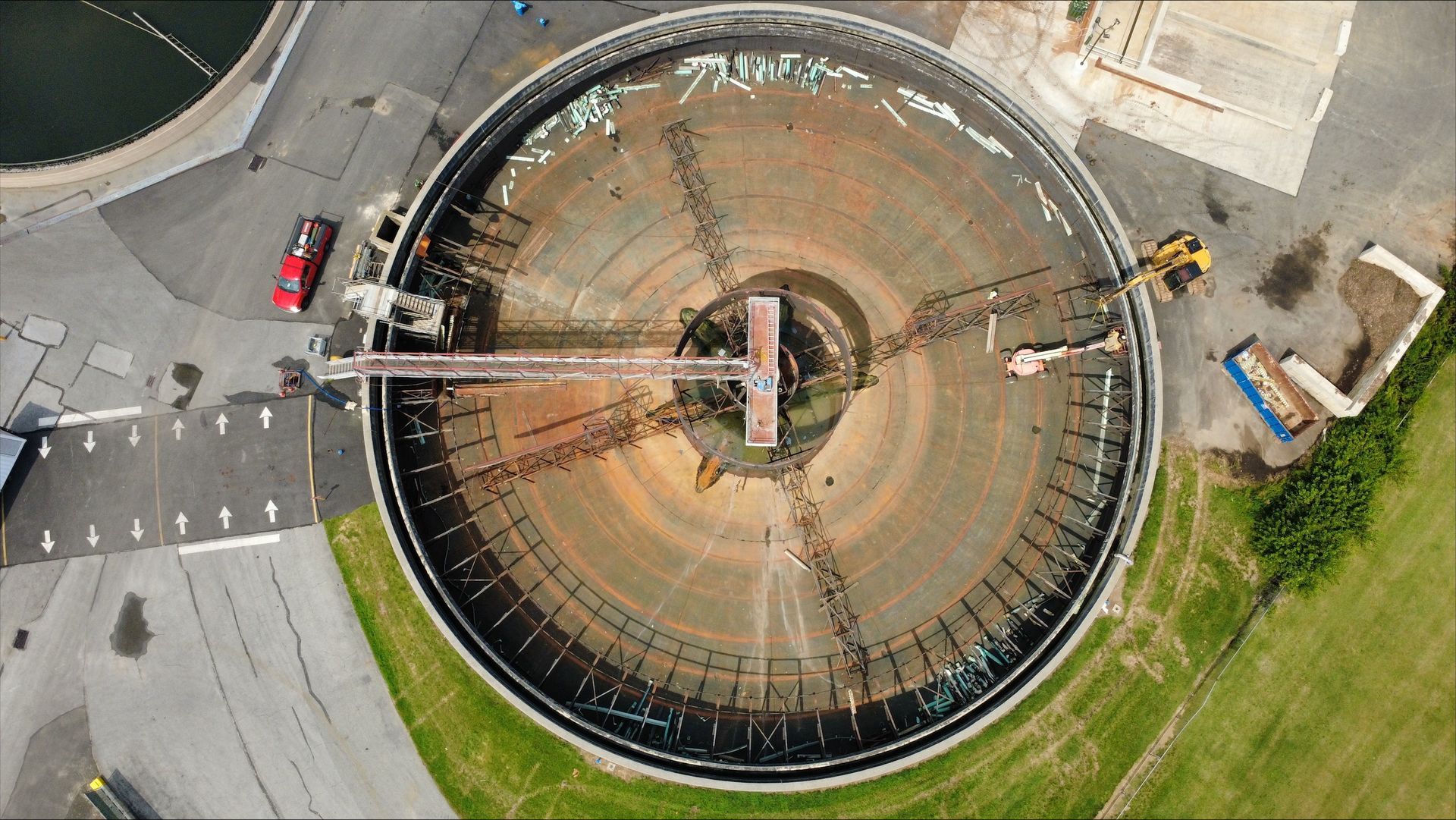

Minsi Lake Park Rehabilitation

In partnership with Northampton County Parks and Recreation, Empire Services took part in phase one of the Minsi Lake rehabilitation project in Bangor, PA. The team excavated and prepared for the new paved pedestrian trails, concrete slabs, and foundations for the new restroom structure. Some of the equipment utilized on this unique project included excavators, skid steers, rollers as well as a subcontracted crane service to place the new restroom structure.

As Pennsylvania continues to evolve, its parks will adapt to meet the changing needs of diverse communities. These parks serve as living monuments, preserving the past while embracing the future of recreation and community engagement. Empire Services is grateful to be part of these park improvements, helping to create all-inclusive and safe spaces. We have the equipment and experience to complete these projects no matter the size of the park or the location.